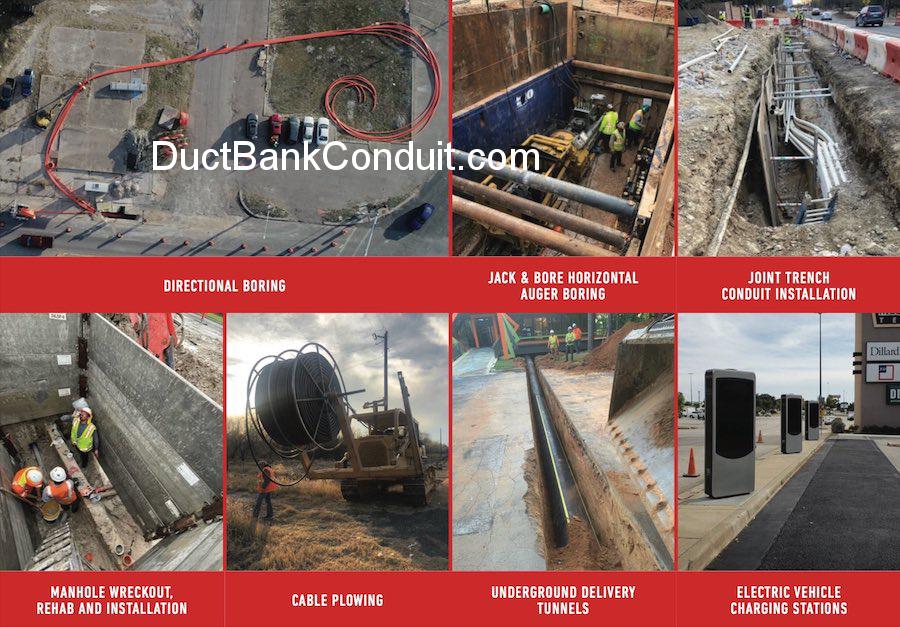

Directional Boring

What is Directional Boring?

Directional boring, commonly called horizontal directional drilling or HDD, is a steerable trenchless method of installing underground pipes, conduits and cables in a shallow arc along a prescribed bore path by using a surface launched drilling rig, with minimal impact on the surrounding area.

Directional Boring, also known as Horizontal Directional Drilling (HDD) is the most efficient method known for installing utilities underground.

Directional boring eliminates the need for trenching or open cutting roadways and other hard surfaces, reducing interruption to traffic and disturbance to landscape as well as existing surfaces.

The trenchless drilling process is used for installing power and telecommunications cable conduits, water lines, sewer lines, gas lines, oil lines, irrigation lines, product pipelines and casings used for environmental remediation.

HDD is used to cross rivers, roadways, congested areas, environmentally sensitive areas and any area where other methods are more expensive or aren’t feasible. Use of the directional boring method is growing rapidly and is expected to increase for the foreseeable future.

Directional boring is used in place of other drilling techniques for the following reasons:

Deeper installation possible

Directional and curved capabilities

Less traffic disruption

Longer installation distances possible

Lower costs

No access pit required

Safer for the environment

Shorter project completion times

Duct Bank Conduit Auger Bore | Horizontal Auger Boring Setup

Duct Bank Conduit Auger Bore | Horizontal Auger Boring Setup

Horizontal auger boring (HAB), also known as horizontal earth boring or jack and bore, may be the best underground option for drilling lengths up to 500 feet and diameters up to 60 inches in variety of soil conditions. Horizontal auger boring can be used to install pipes in changeable ground conditions and, in many cases, has lower overall costs compared to other trenchless methods.

The Horizontal auger bore process uses a revolving cutting head that is located at the leading end of an auger assembly to excavate the soil. Common practice is to jack the steel casing through the excavated hole as it is being bored. The spoil is then transported back to the shaft area by the rotation of the helical auger flights within the steel pipe casing.

Auger boring machines come in different sizes and capacities. Ground conditions usually dictate how powerful of an auger machine is needed. If the ground is sandy or heavy clay, more force is required.

Duct Bank Conduit Auger Bores | Horizontal Auger Bore Pushing Casing

Duct Bank Conduit Auger Bores | Horizontal Auger Bore Pushing Casing

Auger Machine:

The auger boring machine is used to drill earth horizontally by means of a cutting head and auger or other functionally similar device. The machine may be either cradle or track type.

Horizontal auger boring has been used to install utilities for decades. The process has changed over the years as the technology has changed yet auger boring is one of the most cost effective methods of installing utilities. It is considered the first trenchless pipe installation method used by the construction industry.

Auger boring machines can drill in a variety of soil conditions. Clays, sand and shale can be drilled with the basic equipment. Rock can be auger drilled as well but requires special equipment.

In cases where the ground is unstable, a wash-over pipe, or casing, can be pushed through the borehole to prevent the collapse of the hole walls. Some systems use a dual pipe exclusively.

Duct Bank Conduit Auger Boring | Horizontal Auger Boring Railroad Crossing

Duct Bank Conduit Auger Boring | Horizontal Auger Boring Railroad Crossing

Railroad Auger Boring Services

Railroad Auger Boring Services

Horizontal auger boring (also known as auger boring, jack and bore, and various other names is a underground construction method performed by boring from a launch shaft to a receiving shaft. A steel encasement of the desired diameter is installed as the bore and hole advance. A rotating cutting head is attached to helically wound auger flights, which rotate to drive the cutting head and carry the excavated spoil back to the launch shaft. The auger boring process is used from as small as a 6